Division of Mechanical Engineering

Overview of Mechanical Engineering

The Division of Mechanical Engineering of Karunya Institute of Technology and Sciences is known for excellence in academics and research in the field of design & manufacturing engineering, material sciences & thermal management, renewable energy, metallurgy and mechatronics engineering. The department has well established laboratories and state of art research centers to carry out research and development in the thrust areas of food, water, health care and energy. Holistic education with values and ethics are imparted to students allowing them to pursue successful careers in product design, research and entrepreneurship. Students enjoy freedom to express their ideas through interaction with faculty and peers by participating in department technical clubs, research lab activities. This leads students to develop technical skills, innovative products, patents and leadership qualities.

Our Vision

To be recognized globally by providing industry and research-oriented education, raising skilled engineers who are innovative and competent in product development and successful in entrepreneurial and engineering practices.

Our Mission

Apply the engineering problem solving skills to career paths such as engineering education, industrial practice, start-up ventures, patenting and product development.

Conduct research and development resulting in tangible applications that advance technology and foster innovation to compete successfully in the global economy.

Advancing in entrepreneurial ventures that support sustainable economic development to enhance the quality of life of people world-wide.

B.TECH MECHANICAL ENGINEERING

Graduates will have ability to:

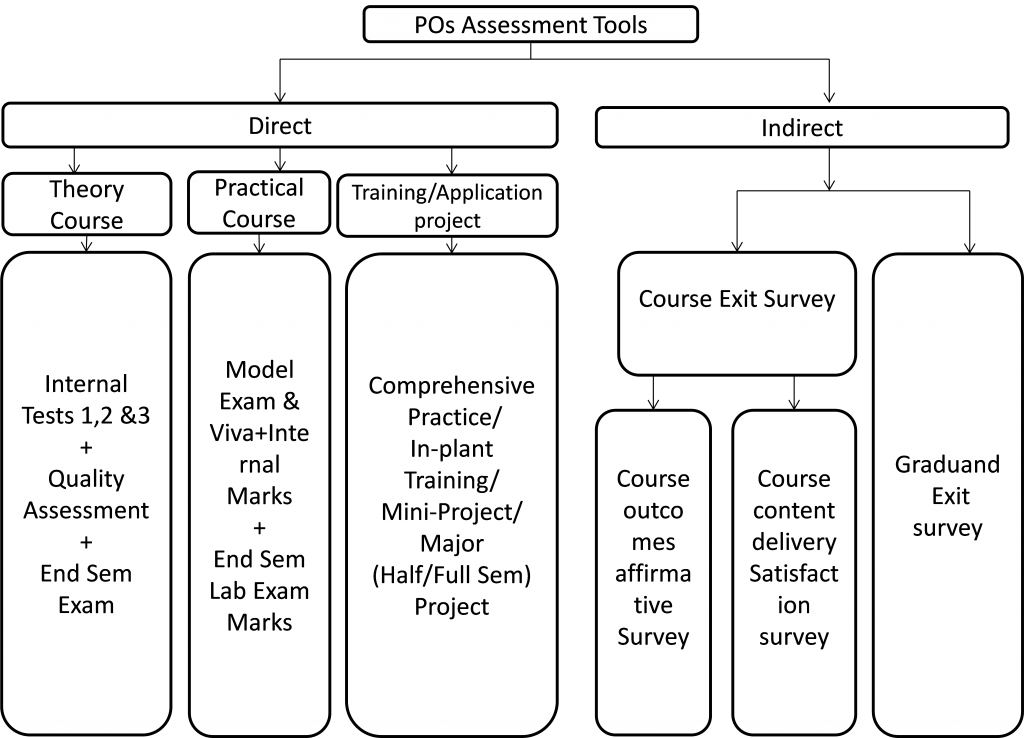

Programme Outcomes Attainment

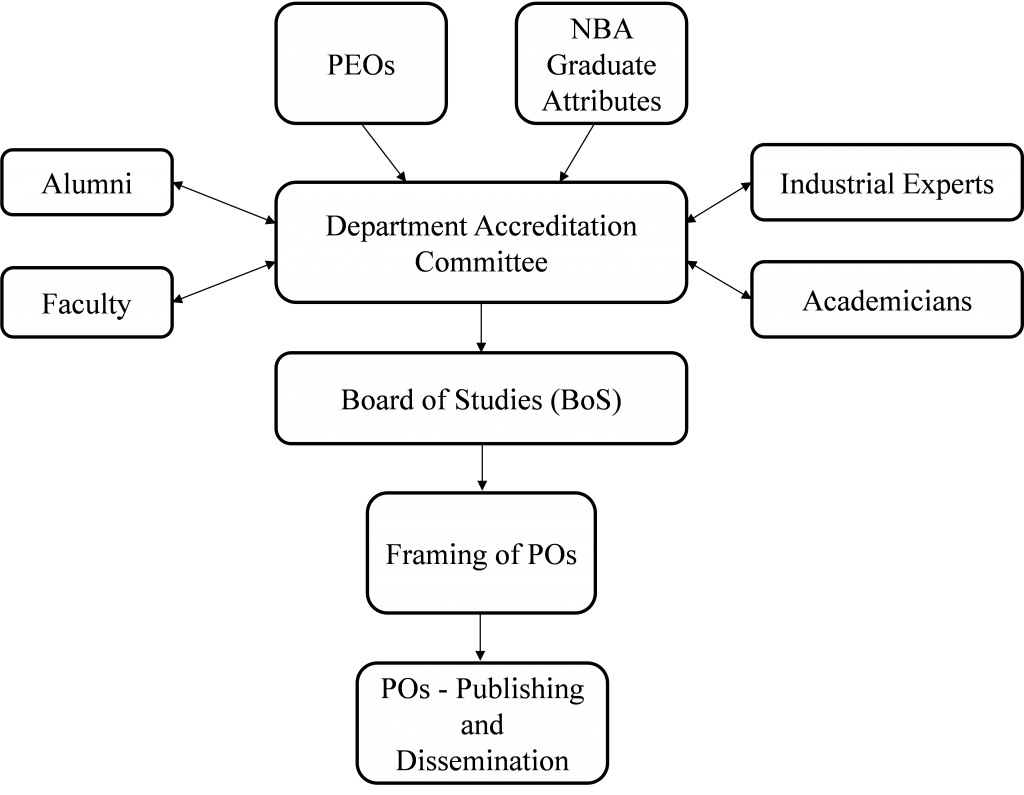

Based on the NBA defined mandatory Graduate Attributes (GAs) and the Programme Educational Objectives (PEOs) of the programme, the members of the Board of Studies have established the Programme Outcomes (POs). These were then passed on to select alumni and the faculty members of the department. Based on the inputs received from them, the POs were presented again to the Board of Studies (BOS) for revision and approval. In total, twelve POs were finalized.

Testimonies by Our Students

Testimonies by our Alumni

TOM NICHOLAS FREEMAN S

TOM NICHOLAS FREEMAN S JOEL VARMA

JOEL VARMA V. NIDHIN

V. NIDHIN K.SUMANTH RATNA

K.SUMANTH RATNA Ashish Christy Varughese

Ashish Christy Varughese Sachin P George

Sachin P George Jewel James

Jewel JamesInternships done Abroad by Our Students

Shawn Jacob (UR15ME151)

Shawn Jacob (UR15ME151)Internship at Rajamangala University of Technology, Thailand

Nihal Kumar (UL15ME013)

Nihal Kumar (UL15ME013)Internship at METALEX GROUP, Ghana from June 2018 to September 2018.

Research Centres

CENTRE FOR RESEARCH IN DESIGN AND MANUFACTURING ENGINEERING (CRDM)

CENTRE FOR RESEARCH IN MATERIAL SCIENCES AND THERMAL MANAGEMENT

CENTRE FOR RESEARCH IN METALLURGY

CENTRE FOR RESEARCH IN RENEWABLE ENERGY

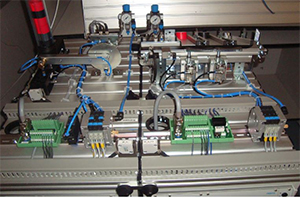

CENTRE FOR RESEARCH IN MECHATRONICS (CFM)

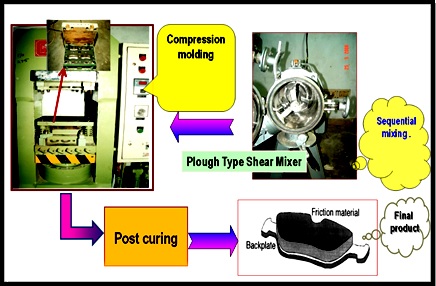

Development of Non- Asbestos Organic Brake Friction Materials

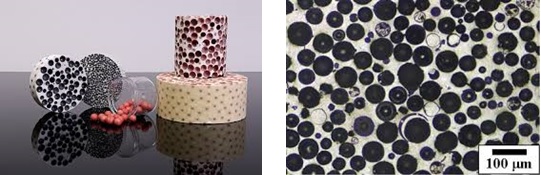

Development of Non- Asbestos Organic Brake Friction Materials  Fabrication and characterization of Al syntactic foams

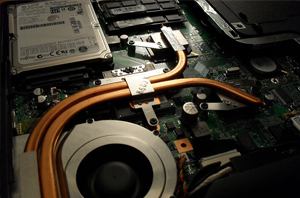

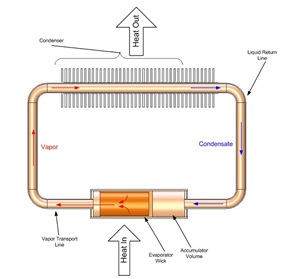

Fabrication and characterization of Al syntactic foams --> Micro and Nano Heat Transfer Laboratory

--> Micro and Nano Heat Transfer Laboratory  Miniature loop heat pipes for cooling high heat flux devices

Miniature loop heat pipes for cooling high heat flux devices  Composites in Combat: Composites for Military Vehicles

Composites in Combat: Composites for Military Vehicles  Biomass waste to energy for automotive applications

Biomass waste to energy for automotive applications  Clean and Green Technology to overcome health risks associated with cutting fluids in manufacturing industries

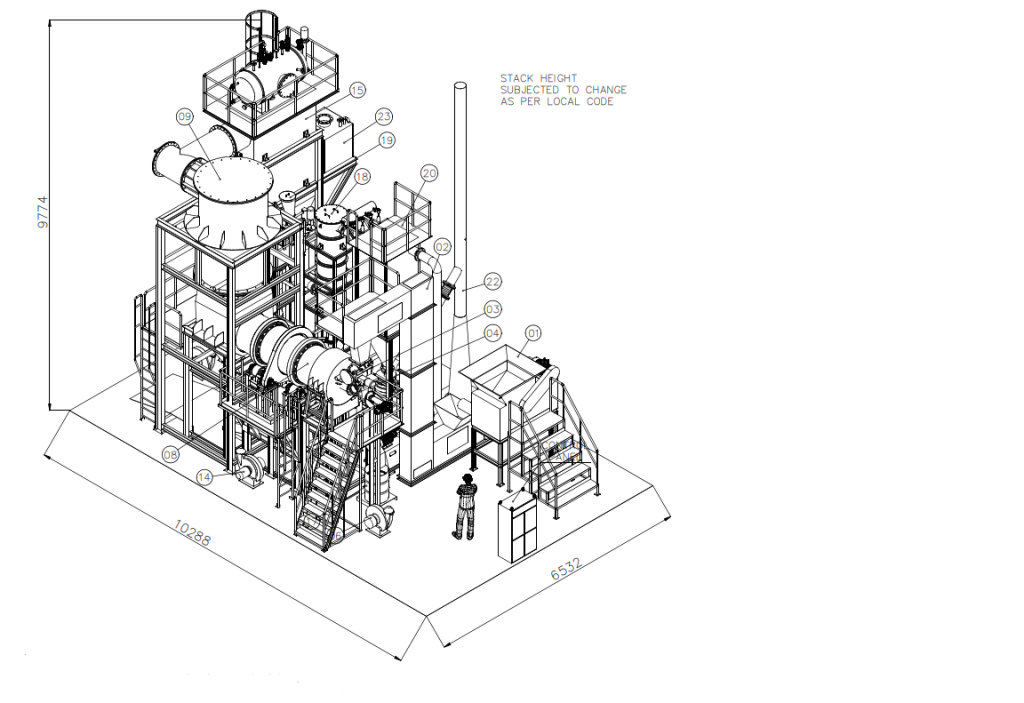

Clean and Green Technology to overcome health risks associated with cutting fluids in manufacturing industries  Design of 2 TPD Rotary Kiln Gasification Pilot Plant with high CV Syngas production

Design of 2 TPD Rotary Kiln Gasification Pilot Plant with high CV Syngas production